According to your needs

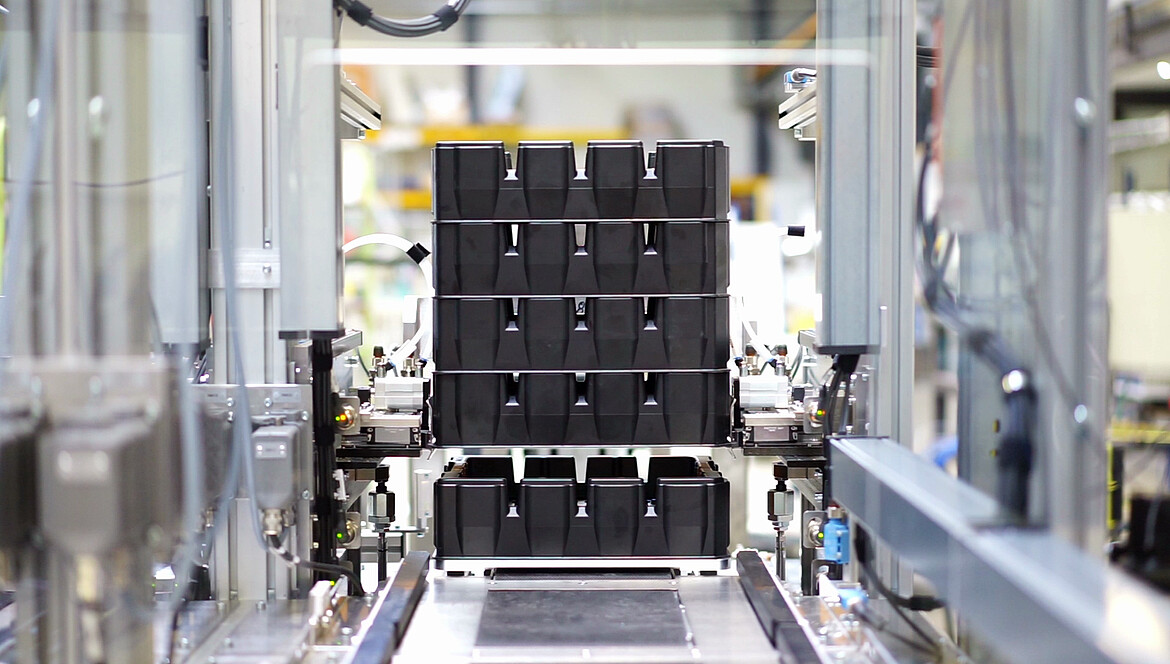

Our scalable palletizing systems adapt flexibly to any cycle time and supply height and process all common container and product types. In this way, they support demand-oriented material flow and create autonomy in factory automation. Our systems are designed to destack, load, unload, and restack standardized containers such as blisters, trays, or KLTs. Thanks to individually adjustable belt lengths, variable container sizes, and high modularity, they can be easily integrated into existing lines – regardless of cycle time, space requirements, or process structure.

Stack loading can be performed using a wide variety of material handling equipment. Fast container changeover and a wide range of loading and unloading options are great strengths of our palletizing and depalletizing systems. We manufacture according to your needs: whether as a single module or a complete solution. From simple storage to individual loading and conveying of your containers using robot grippers, we offer an extremely wide range of options – ensuring maximum flexibility combined with high process stability.

Variable for every cycle time and staging height

The palletizing systems adapt flexibly to your production speed and space requirements – without any time-consuming retooling.

Load capacity up to 500 kilograms

Even heavy containers or large products are reliably transported and stacked – for efficient processes in your production.

Particularly low noise emission

Quiet operation protects machines and employees and ensures a pleasant and safe working environment.

Fast container change

Containers can be easily exchanged, allowing your production to respond flexibly to changing requirements.

Versatile loading and unloading options

Pallet stacks can be loaded and unloaded either automatically via driverless transport systems (AGVs) or conventionally by operating personnel using trolleys or conveyor belts.

Orderly Material Flow – Step by Step

Our palletizers and depalletizers combine ease of use with reliable technology: Trays, blisters, KLTs, or pallets are picked up via transport or roller systems, automatically destacked, and made available at a transfer position. There, the loading or unloading takes place – either by robots or other handling devices. The containers are then restacked and transferred to the next process stage.

This orderly feeding process and fast tray change protects the surfaces of sensitive or complexly shaped workpieces, minimize production interruptions, and enable integration into automated production lines. For heavy tray stacks, the system can be optionally expanded with docking stations for transport trolleys or a fully automated transfer to floor-borne vehicle. Linking multiple systems for higher capacities is also easily possible.

Our palletizing and depalletizing systems stand for the highest quality and efficient processes. You benefit from:

Whether as a single module or a fully integrated solution – our technology adapts to your requirements and ensures stable and reliable operation.

Would you like to know more? For further information on our feeding systems or feeding modules, we kindly refer to the specific product descriptions.

If you are interested, please get in touch with us.