IFSYS and EMSO. Made in Germany.

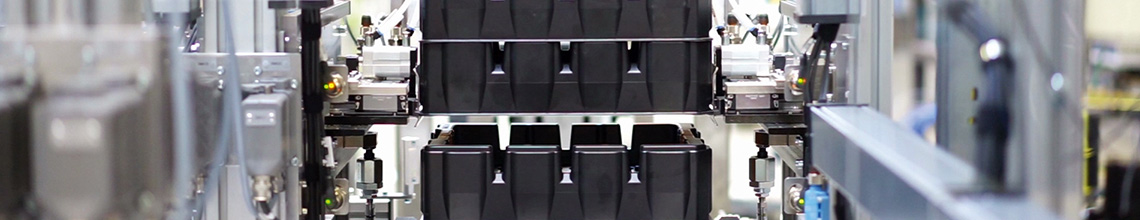

The technology portfolio consists of feeding systems and customised machines, which support automation and the Industry 4.0 environment or the semi-automated assembly lines of our customers. A core competence is technically sophisticated component feeding systems, as a combination of precise mechanical engineering and innovative control engineering from a single source.

Our engineering services range from planning and design with 3D CAD, the application of conventional and leading-edge CNC techniques, electrical equipment production, the assembly of mechanical and pneumatic components, as well as assembly with the integration of measuring and test equipment, right through to handling technology and robotics. Added to this come programming, control units, as well as optical and sensory assistance systems. 3D printing is becoming increasingly commonplace in the production process. With this know-how we practice “learning by doing”, and we produce individual components in this way.

The extensive depth of production not only guarantees competitive advantages, but also offers direct customer benefits through precisely tailored automation solutions, optimum connection with the complete system and plant availability. Through the use of these technologies, IFSYS and EMSO are also an attractive employer for experts and specialists.

Products and processes at a glance.

Through applied research and development, the in-house development department delivers product optimisation and the planning of new products, the formulation of constructive solutions and the transfer of technology. This includes investigations, analyses and tests, benchmarking and increased benefits. It is often the minor improvements, which arise due to ideas and lateral thinking, that result in a significant advantage in production or application.

Development concepts pertain to mechanical and electronic components, software, materials, processes, data networking, as well as the interaction between human and machine. Because ideas, concepts and improvements originate from the mind, an organised and constant exchange takes place between all employees in development, design and engineering.

Mechanical and electronic development is part of the innovation process with the aim of optimising functions, researching technical alternatives, reducing weight, digitalisation, maximising safety, reducing production costs, optimising ergonomics and design, as well as recyclability. We are frequently involved in co-engineering with customers, for solutions that impress in every regard - technically and economically.

Planing and controlling. Throughout the entire project.

Our project management division takes care of the seamless realisation of projects and acts as a link between the customer, sales, product development, production planning and quality assurance.

Planning and controlling from the first solution approach, right through to assembly and commissioning - competent, flexible and targeted. That means interface assurance, the customer order is defined as a complete process including resources and deadlines, and is supported right through to the completion phase.

Quality. With assurance.

IFSYS and EMSO deliver first-class quality products. A QM system is implemented in order to continuously safeguard quality targets. The company adheres to standardised and documented processes, which are further developed in accordance with customer requirements. Auditing and certification take place in accordance with QM standard DIN ISO 9001 and environmental standard ISO 14001.

We pursue a holistic quality concept that encompasses management responsibility right through to the continuous improvement process. The resultant customer advantage lies in planning and product assurance, batch purity in production, high quality, product traceability, system partnership and innovative strength.

Fully in sync. And flexible.

Manufacturing by IFSYS and EMSO.

The customer requirements for feeding technology for application in series production or assembly include shorter production times, variant changes, new materials and coatings for example. High production competence, depth of production and system understanding make IFSYS and EMSO a competent point of contact for sophisticated projects - with individual and complete solutions, components and reproducible systems.

The equipment of machines, systems and plants, which are constructed with internal know-how, takes place on the basis of the latest engineering practice. This results in the combination of advantages such as high flexibility, adaptability and customised, innovative solutions. The production processes and workflows are flexibly oriented, networked and increasingly digitalised in accordance with the principles of individual production and customised machine construction.

IFSYS and EMSO is a partner and system supplier on the research project freeMoVe. This project for versatile assembly systems through free networking, which is funded by the Federal Ministry of Education and Research, is being project managed by the machine tool lab/WZL of RWTH Aachen University.

Quality and precision.

In our own production, we trust our systems with modern manufacturing technology. Our main competence is the milling technology with our CNC milling machines. Quality and precision are paramount for our company.

Customer focus. We are here. Dependably.

At IFSYS and EMSO, customer relationships are based on advice, engineering and service. With this attitude, we advise, develop, simulate and design, we search and find an expedient solution for (almost) everything, and we stand ready to provide our customers with advice and support at all times. Fairness and trust are the keys here to successful and long-term cooperation.

Following assembly and commissioning, we offer a comprehensive range of services for all equipment and devices: Service and maintenance work, qualification of customer personnel on site, overhauls, original spare parts, as well as conversion and repairs. Performed reliably and flexibly by service personnel who are highly familiar with the technology.