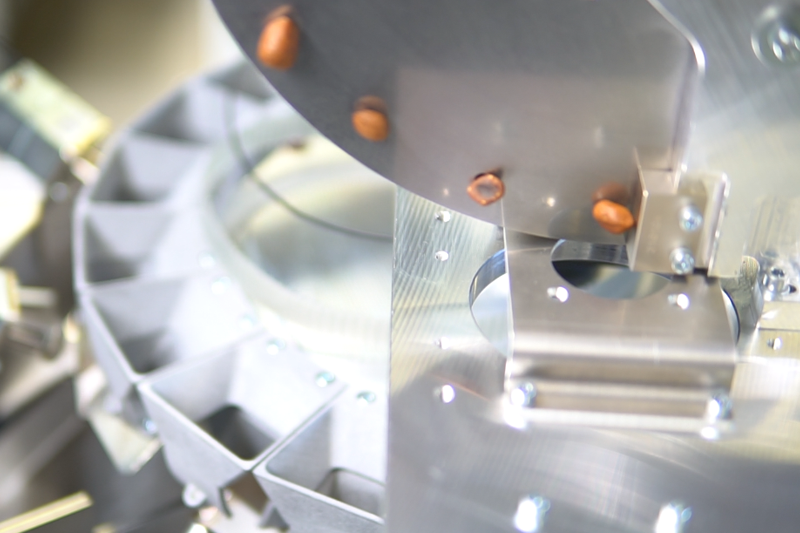

Step conveyors and sorting rail - our core competence

Our core competence is feeding technology, our strength is adaptability in every respect. No matter which parts or assemblies have to be fed into the production process, we offer the right solution for almost any requirement. On request with integrated devices for measuring, testing, weighing, counting and packaging.

In-house development and a high level of vertical integration, competent engineering, precision machining and electrical production - everything from a single source. Made in Germany.

With feeding technology from IFSYS, high feeding performance with low noise emissions, maximum protection of parts and low susceptibility to faults can be implemented, as can flexible use, compact dimensions and interchangeable components.

Just like our other feed systems (e.g. spiral conveyors and drum conveyors), the step conveyors from IFSYS are characterized by their well thought-out design, optimal feed performance and high reliability.

The step feeder is one of the most frequently used feeding systems and is mainly used for pre-sorting and metered feeding of the IFSYS Vibroliner®.

The Vibroliner® is one of the core of the innovative strength of IFSYS. Thanks to good scalability and the wide range of integration options, Vibroliner® technology in combination with other feeding systems forms the basis for optimum quality and reliability.

Always the perfect solution

We are guided by you and your demands: There is almost nothing in the world of feeding technology, which we do not make possible for you. No matter whether it's tubes, rods or Ball feeders, spiral conveyors, storage or lift systems, sorting technology, desentangling technology, testing technology or measuring technology - we have designed and built. The right solution for your needs.

According to your needs

Our palletizing systems are variable for every cycle time and staging height all common containers and product types can be stacked and loaded - and this with extremely low noise emission. Quick container change, exact scalability and A wide range of loading and unloading options are the great strengths of our products.

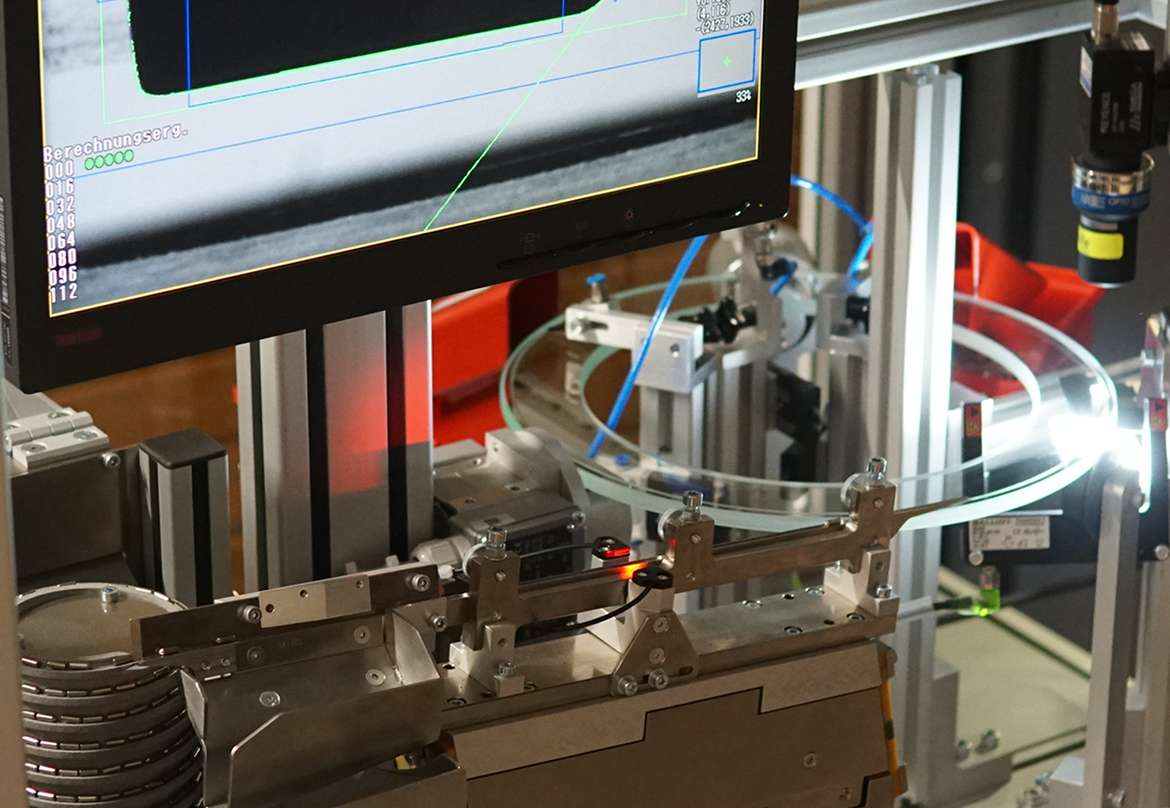

Complete package in test automation and measurement technology

Everything from a single source - we at IFSYS live up to this claim. Your company is also aiming for simplified processes and short business channels. As a specialist for feeding technology, we have expanded our range to include integrated measuring technology - we thus provide you with the complete package in terms of test automation: fully automatic feeding, measuring with powerful camera systems and sorting for the further production process.

Screw and screwdriver come together

IFSYS feeders are suitable for a wide range of screws. Both for the gentle handling of aluminum screws, as well as for other different sizes and types. Of course, we also supply the complete package here: screwdriving technology with individual feeding technology for manual, semi-automatic or fully automatic applications.

360° - all around view and classification of your sorted goods

Sorting goods with demanding, changing geometries can be sorted and classified using optical sorting technology. This enables simple and fast further processing. Optical sorting technology is a tailor-made solution for a specific sorting material, but can also be used to process different sorting materials if required. Optical sorting technology from IFSYS is your guarantee for the quality of your products.

Flexible supply of parts with a vibration system

Our answer to variable part feeding tasks.

Especially for applications with frequently changing part geometries, Flexible Feeding Technology is a good solution. Both small, delicate parts and large, heavy parts can be sorted, aligned and fed. The interaction of robot, feeding system and integrated image processing also allows many different parts to be processed in small batch sizes

Special machine construction under customer-certified cleanliness

Specially trained personnel, detailed planned assemblies and precisely planned procedure descriptions are the prerequisites for our work in the clean room. Customer-certified cleanliness, defined process chains and trained specialist personnel are our keys to your project success. Customers from a wide range of industries, such as automotive, medicine or pharmaceuticals, have already benefited from our performance here.

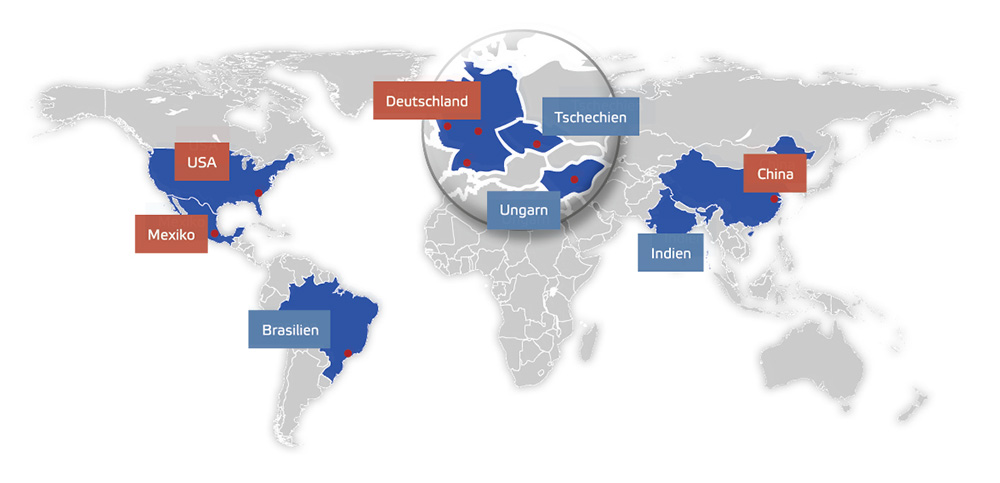

+ Germany

+ Mexico

+ USA

+ China