For more efficiency in production

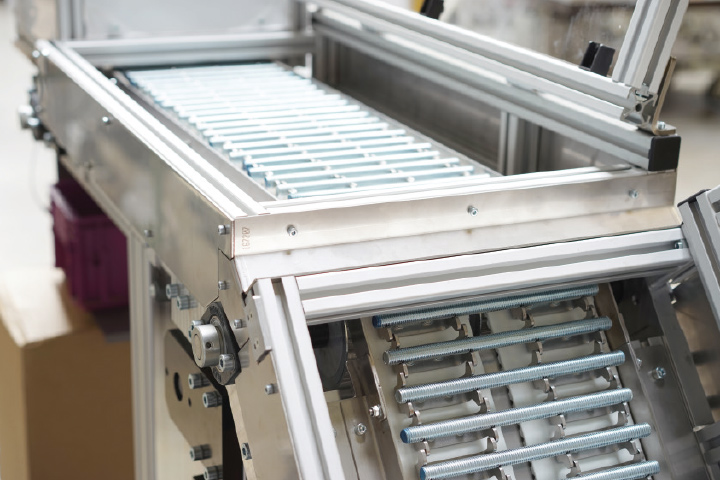

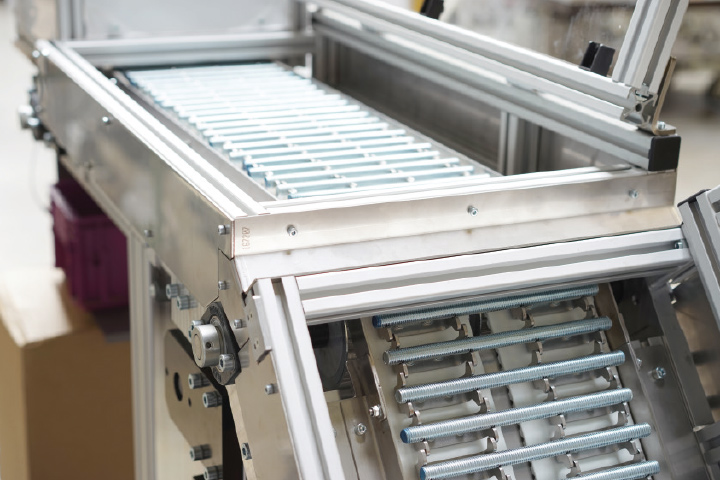

Our core competence is feeding technology. We rely on proven components: Our step feeder is one of the feeding systems that is most widely used. They are characterized by a well-thought-out construction, optimal feeding performance and high reliability. The gentle handling of the conveyed parts, a low noise pollution and the fulfillment of special requirements round off the advantages. Our step feeders are primarily used for pre-sorting and dosed loading of our VIBROLINER.

The VIBROLINER is the heart of the technology at IFSYS. Thanks to a wide variant of sizes and many integration options, the use of VIBROLINERS in our feeding systems is the basis for optimum quality and reliability in part feeding. With the use of a VIBROLINER, parts feeding is gentle and quiet. Compared to other linear vibratory conveyors, the VIBROLINER has a low profile as well as the ability to utilize exchange tooling.

Always the perfect solution

We are guided by you and your demands: There is almost nothing in the world of feeding technology, which we do not make possible for you. No matter whether it's tubes, rods or Ball feeders, spiral conveyors, storage or lift systems - we have designed and built. The right solution for your needs.

Feeding technology for magnets: IFSYS convinces with many years of experience, especially when precise parts provision and high conveying capacities are required. Feeding systems from IFSYS convince with a gentle, almost damage-free, fast and precise provision for the transfer and transfer of non-magnetized magnet blanks. Concepts for batch tracing, fast changeover for type changes and devices for setting the magnets are among the special developments of the IFSYS magnet feeders.

The IFSYS tube and bar feeders can be adjusted for all material diameters and lengths, and offer a wide range of test options. Equipped with variable transfer height and a high feeding capacity of up to 120 parts/minute.

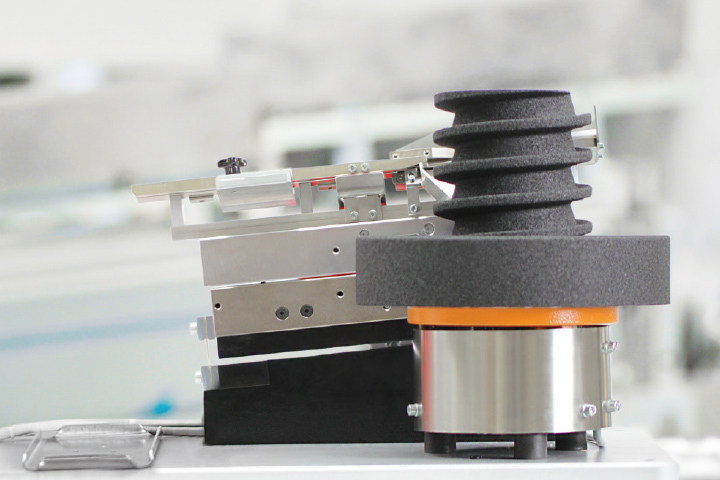

The IFSYS ball feeders with geared motor are variably configured for spheres with a diameter of 3.9 to 24 mm (other diameters on request). The output is up to 360 parts material feed/minute.

Also extremely reliable in tough continuous operation: The IFSYS spiral feeders can be individually adjusted to almost all bulk goods. Fault-free transfer from round to linear with the IFSYS external spiral systems. Ideal for combination with tried and tested IFSYS technology.

The IFSYS storage systems are the solution for manual loading, which is possible on multiple tracks and on multiple levels. Suitable for combination with the IFSYS separation and test systems.

Would you like to know more? For further information on our feeding systems or feeding modules, we kindly refer to the specific product descriptions.

If you are interested, please get in touch with us.